Boilers are essential for heating, manufacturing and sterilization, but scaling and corrosion are twin threats lurking in every commercial and industrial boiler room. Licensed professionals tasked with keeping these systems running safely and efficiently must understand the science behind these issues and how to prevent them from causing damage.

Learn how to bridge chemical theory with practical, actionable strategies for diagnosing, monitoring and preventing scaling and corrosion in boilers. This guide is a comprehensive, technician-focused resource that equips you with the knowledge and tools needed to troubleshoot efficiency drops, implement proactive maintenance programs and protect your boiler investment.

Scaling and Corrosion Problems in Boilers

Before you can control scaling and corrosion, you need to understand what they are and how they differ. While both are forms of boiler “attack,” their mechanisms, symptoms and solutions are distinct.

Scaling

Scaling is a challenge that can significantly impact performance and reliability. For example, in a food processing plant, untreated hard makeup feedwater can lead to rapid scale buildup inside boiler tubes. Over time, this results in a noticeable drop in steam output and a spike in fuel consumption.

Every technician can recognize and remedy these characteristics and consequences of scaling.

- Deposits of mineral solids, often calcium, magnesium and silica, on internal boiler surfaces.

- These deposits accumulate into hard, insulating layers that obstruct heat transfer and can cause localized overheating.

- Scaling is most common in areas of high temperature and evaporation, like boiler tubes and heat exchangers.

Corrosion

Corrosion is a serious threat to equipment integrity and operational safety. For instance, a facility using improperly treated feedwater may experience oxygen pitting in the boiler drum. This phenomenon can lead to small but deep holes that may eventually cause leaks or catastrophic failure of a boiler system.

When monitoring boiler corrosion and its causes, consider the following defining features:

- The electrochemical degradation of metal surfaces often results in pitting, thinning or rust formation.

- Dissolved oxygen in boiler system water, low pH, carbon dioxide and other aggressive ions in the water lead to corrosion.

- These issues can occur throughout the boiler system, including feedwater lines, boiler tubes and condensate return.

The Chemical Difference Between Scaling and Corrosion

Scaling results from physical deposits in a boiler system, while corrosion is a chemical or electrochemical attack on metal. Both phenomena reduce efficiency and threaten system integrity, but they require different monitoring and control strategies. Understanding the distinction is essential for effective diagnosis and treatment.

A technician’s best defense is a solid grasp of the chemical reactions that cause scale and corrosion in boilers. This section breaks down the root causes and water chemistry parameters to control.

Scaling

Scaling in boiler systems results from heating and concentrating water during operation. As ions like calcium, magnesium and silica become supersaturated, they react to form solid deposits on internal surfaces. For example, calcium ions combine with carbonate ions to form calcium carbonate scale, while magnesium ions react with silicate ions to produce magnesium silicate scale.

The risk of scale formation increases in environments with high alkalinity, elevated total dissolved solids and higher operating temperatures. These factors speed precipitation and the buildup of insulating layers.

Corrosion

Corrosion in boiler systems is due to a series of electrochemical reactions that degrade metal surfaces. One of the most typical forms is oxygen corrosion, where iron reacts with dissolved oxygen and water to form iron hydroxide, commonly known as rust. Another cause is carbon dioxide corrosion, which can occur when carbon dioxide dissolves in water to form carbonic acid, lowering the pH and aggressively attacking metal components.

The risk of corrosion increases in conditions with low pH, high levels of dissolved oxygen and the presence of aggressive ions like chlorides or sulfates, all of which can accelerate the breakdown of metal surfaces.

Water Quality Parameters

Technicians can closely monitor several critical water quality parameters to control scaling and corrosion problems in boilers, including pH, alkalinity, hardness, silica, dissolved oxygen, total dissolved solids and conductivity.

Regular testing and adjustment of these parameters are essential for maintaining boiler performance and preventing the onset of scale and corrosion.

How Scaling and Corrosion Impact Boiler Performance and Safety

Unchecked scaling and corrosion in boilers can lead to catastrophic failures, costly downtime and regulatory violations. Here’s what’s at stake.

- Efficiency losses: Even a millimeter-thick scale layer can reduce heat transfer efficiency and increase fuel consumption by 5% to 8%. Corrosion can cause leaks and thinning, leading to heat loss and reduced steam output.

- Safety hazards: Scale can cause localized overheating and tube failure, risking explosions, while corrosion may result in ruptures, leaks and dangerous steam releases.

- Cost implications: Scaling and corrosion problems in boilers can increase energy bills and lead to frequent repairs, unplanned shutdowns and shortened equipment lifespan. In addition, regulatory fines or insurance issues may result from violating safety standards.

Signs and Testing Protocols for Diagnosing Scaling and Corrosion

Early detection is critical. Technicians should learn the telltale signs of scale and corrosion and the testing protocols to prevent them from escalating.

1. Visual and Operational Clues

Diagnosing boiler issues requires vigilance and a sharp eye for visual and operational clues. When scale is present, seasoned professionals may notice a reduction in steam output, increased fuel consumption and the development of hot spots on boiler surfaces. Noisy operation and visible mineral deposits during inspection can also indicate scaling.

In contrast, corrosion often shows up through these symptoms, which can signal underlying chemical imbalances or the presence of aggressive ions in the water.

- Rust stains

- Pitting

- Leaks

- Thinning metal

- Unexplained pressure drops

- Water discoloration

2. Testing Protocols

Using rigorous testing protocols is the best way to catch and address these issues. Regular water sampling and analysis for parameters like pH, hardness, alkalinity, silica, dissolved oxygen and TDS provide a detailed picture of water quality.

Using specialized test kits and meters for on-site, real-time monitoring allows technicians to detect deviations before they snowball out of control. Scheduled shutdowns should always include a thorough inspection of boiler internals to check for hidden scale deposits or corrosion damage.

For those seeking advanced solutions, AquaPhoenix Scientific supports precise, on-the-spot analysis for maintaining optimal boiler protection. These include test kits using Rose Bengal chemistry to measure residual corrosion inhibitors in boiler systems, like film-forming amines.

3. Documentation

Documenting all findings and maintenance actions in a digital or physical logbook of test results, operational changes and corrective measures allows for effective trend analysis.

By tracking these data points over time, technicians can spot gradual changes in system performance and intervene before minor issues become critical failures. This proactive approach safeguards equipment and supports regulatory compliance and operational efficiency.

Proactive Prevention Strategies for Scaling and Corrosion

Preventing boiler water scaling and corrosion is always more cost-effective than repair. Here’s how to build a robust, proactive program to keep scale and corrosion at bay.

Water Treatment Fundamentals

Effective boiler water treatment starts with pre-treatment processes like softening, reverse osmosis or demineralization to remove hardness ions and silica from the feedwater. These are essential for minimizing the risk of scale formation and protecting boiler component longevity.

Chemical dosing will further protect the system:

- Scale inhibitors like phosphates and polymers keep minerals dissolved in the water, preventing them from depositing on boiler surfaces.

- Oxygen scavengers, including sulfite, DEHA or hydrazine, eliminate dissolved oxygen, which is a primary driver of corrosion.

- Introducing pH adjusters as needed maintains optimal alkalinity, creating a stable environment that discourages scaling and corrosion.

Automated Monitoring and Control

Modern boiler systems benefit from automated chemical feed and monitoring systems, which lock in consistent dosing and provide real-time alerts if water chemistry deviates from set parameters. These systems can integrate with supervisory control and data acquisition or distributed control systems for data logging and remote oversight.

This interaction streamlines operations and allows workers to respond quickly to potential issues, reducing the risk of costly downtime.

Routine Maintenance

Routine maintenance and repair are the foundation of any successful boiler water treatment program. The American Society of Mechanical Engineers Boiler and Pressure Vessel Code provides a definitive source of data for boiler maintenance, inspection and operation.

Scheduled blowdown procedures remove concentrated impurities from the system, addressing boiler water scaling and its prevention to avoid scale and sludge buildup. Regular inspection and cleaning of boiler internals are also critical because they enable technicians to identify and address early signs of difficulties before they escalate.

Staff Training

Finally, ongoing education and training for staff are vital to maintaining an effective water treatment program. Regular instruction on water chemistry principles, the latest testing protocols and appropriate emergency response procedures prepare a team to manage challenges and uphold the highest standards of boiler operation and safety.

The Technician’s Toolbox — Essential Testing and Measurement Equipment

Accurate, reliable testing is integral to any successful water treatment program. Here’s what every boiler professional should have in their arsenal.

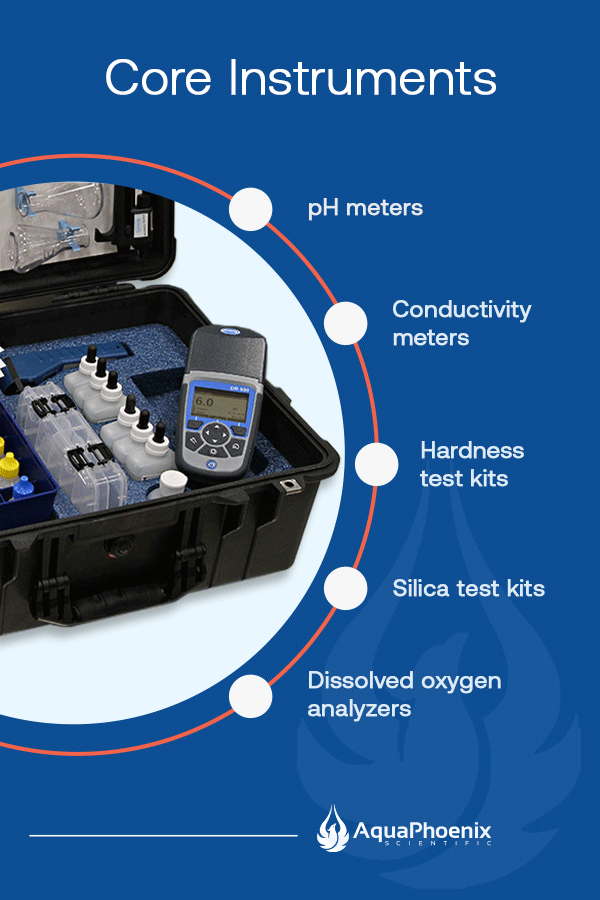

Core Instruments

To monitor and manage boiler water quality, technicians depend on a suite of core instruments designed for accurate and reliable testing. The following tools are available in portable and bench-top formats, making them suitable for on-site field assessments and detailed laboratory analysis:

- pH meters

- Conductivity meters

- Hardness test kits

- Silica test kits

- Dissolved oxygen analyzers

Best Practices

Following established best practices when testing boiler water leads to accurate and consistent results. These guidelines help technicians maintain instrument reliability and data integrity, whether working in the field or the lab:

- Rinse and clean testing equipment thoroughly after each use to prevent cross-contamination.

- Record calibration dates and maintenance activities in a dedicated logbook for traceability.

- Perform routine checks for signs of wear, damage or expired reagents and replace as needed.

- Train all users on proper handling and operation of each instrument to minimize user error.

- Periodic proficiency testing or inter-laboratory comparisons verify measurement accuracy.

- Keep instruments and reagents in a controlled environment to avoid exposure to extreme temperatures or humidity.

Building a Culture of Prevention Through Documentation, Training and Continuous Improvement

Fostering prevention through multiple avenues is vital for long-term success. Vigilance and a commitment to refining practices prevent boiler scaling and corrosion. The following soft skills reinforce technical solutions and embed them into daily operations.

- Documentation: Keep detailed records of water quality, maintenance actions and system changes. Use digital logbooks for easy trend analysis and compliance reporting.

- Training: Regularly update staff on new testing methods, treatment technologies and safety protocols. Encourage knowledge sharing and cross-training among team members.

- Continuous improvement: Review and refine water treatment programs based on performance data and incident reports and stay current with industry best practices and regulatory changes.

Protecting Your Boiler Investment

Scaling and corrosion are persistent, but they’re not inevitable. With knowledge, tools and a proactive mindset, technicians and operators can understand the mechanisms behind scaling and corrosion in boilers, recognize early warning signs, protect critical equipment and maintain reliable operations.

Regular water conditioning is vital. It allows early detection of potential issues and supports data-driven decision-making. Along with a culture of continuous improvement where teams consistently review results, update protocols and invest in ongoing training, this proactive approach ensures boiler systems remain safe, efficient and compliant for the long term.

Partner With AquaPhoenix Scientific for Reliable Boiler Water Testing Solutions

Are you ready to take control of your boiler’s health? AquaPhoenix Scientific is your partner in preventing boiler scaling and corrosion. We offer:

- Comprehensive boiler water testing kits and reagents for all parameters.

- Fast, reliable delivery and expert consultation.

- Support for building and refining your water treatment program.

Contact us today to discuss your facility’s needs and learn how you can leverage our expertise to implement a robust, data-driven prevention strategy.