The oil and gas industry performs complex, high-demand operations. The criticality of these tasks emphasizes the need for quality testing and treatment options that enhance efficiency, maintain product control, and ensure worker and environmental safety. This article explains more about oil and gas industry testing.

Benefits of Testing in the Oil and Gas Industry

Testing is fundamental to nearly every stage of oil and gas operations. From exploration to processing, oil and gas teams must have access to efficient equipment, accurate information and safe working conditions. Testing allows teams to:

- Ensure worker and environmental safety.

- Inform decision-making about field development.

- Optimize production with improved efficiency and maximum recovery.

- Protect equipment and infrastructure from corrosion, scaling and other risks.

- Meet product quality expectations by preventing contamination and meeting specifications.

- Support regulatory compliance to meet environmental standards and avoid fines or shutdowns.

- Protect the environment from hazardous substances and prevent soil, water and air contamination.

Common Tests in the Oil and Gas Industry

Water is vital for industrial operations in the oil and gas industry. Production processes, including drilling, fracking, refining and enhanced oil recovery (EOR), require water to maintain productivity. However, water contaminants can impact oil recovery rates, maintenance costs and equipment efficiency. Impurities in wastewater can also affect surrounding wildlife and the environment, potentially leading to compliance issues or legal implications.

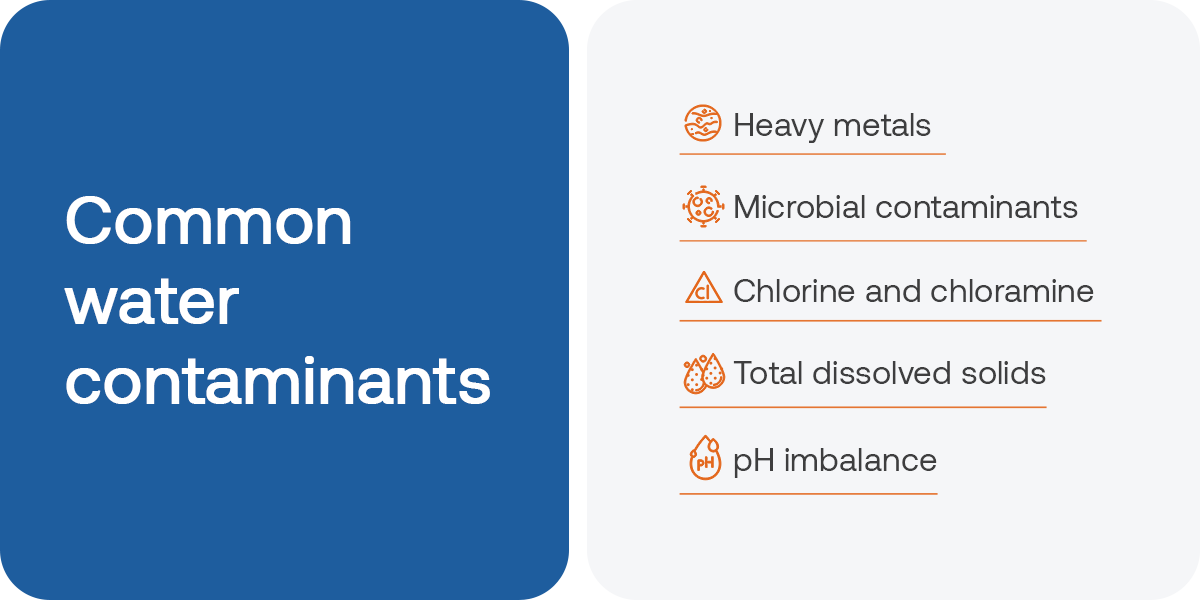

Common water contaminants include:

- Heavy metals: Arsenic, mercury, lead and other heavy metals can significantly impact human health and the environment. Heavy metals in wastewater can cause oil and gas equipment corrosion, affect chemical processes and harm surrounding wildlife.

- Microbial contaminants: Viruses, bacteria and other contaminants can negatively impact water quality. These pathogens can create health risks and result in potential legal liabilities. Bacteria and fungi thrive in oil and gas environments, which can cause issues like formation damage, souring or corrosion during various application stages.

- Chlorine and chloramine: While these substances can disinfect water, excessive amounts can create unpleasant odors and harm wildlife that consumes wastewater.

- Total dissolved solids (TDS): High TDS levels indicate high concentrations of substances like minerals, metals and salts. These substances can cause scaling in machinery or piping and impact the taste of water.

- pH imbalance: Imbalances in water pH can accelerate equipment and pipeline corrosion, cause scale buildup, and impact the effectiveness of chemical treatments in oil and gas operations.

Oil and gas teams can leverage several common tests to identify these water impurities and determine proper treatment. These tests include:

1. Water Quality Analysis

Poor water quality can negatively affect equipment and processes. Scaling and corrosion can reduce equipment efficiency, and contaminants can alter the density and viscosity necessary for drilling. Poor water quality can also lead to hazardous gas formation, which can severely harm workers and wildlife. Furthermore, oil wastewater treatment is critical for meeting environmental compliance.

Water quality analysis tests aim to identify substances and conditions that could pose health and safety concerns, contaminate bodies of water or soil, and negatively impact equipment and processes. These tests are:

Total Dissolved Solids

TDS measures the content of organic and inorganic substances dissolved in water. This test often uses gravimetric methods or conductivity meters to gather measurements. Gravimetric methods are lab-based approaches that involve evaporating water and weighing the remaining residue. Conductivity meters examine water’s electrical conductivity. Higher conductivity levels indicate a higher number of TDS present.

Total Suspended Solids (TSS)

Materials suspended in water or wastewater, such as wastes and silt, are TSS. Monitoring TSS levels is crucial for assessing water quality and ensuring compliance with environmental regulations. To determine TSS levels, teams filter water, then dry, weigh and evaluate the residue remaining on the filter.

Oil and Grease

An oil and grease test measures the amount of hydrocarbons in water. Oil and grease can harm the environment and impact machinery function, making it crucial to remove them before reusing or discharging water. Generally, analyzing oil and grease levels involves collecting water samples, adding suitable solvents, and separating the substances to determine the total oil and grease present. Other methods, including infrared spectroscopy and silica gel treatments, can provide additional insights into quantifying oil and grease.

Ions and Metals

Ions and metals tests look for specific dissolved ions, such as sulfate, sodium, magnesium, calcium and more. Certain ions cause scaling, corrosion and environmental risks, making it crucial to test for them. Teams can use on-site or laboratory analysis to assess ions and metals. On-site methods include leveraging rapid testing kits and continuous monitoring systems. Laboratory analysis may involve ion chromatography (IC), atomic absorption spectroscopy (AAS), inductively coupled plasma mass spectrometry (ICP-MS) or inductively coupled plasma optical emission spectrometry (ICP-OES).

An IC analysis involves separating and quantifying ions, while AAS techniques measure the concentration of specific elements by analyzing light absorption. ICP-OES uses plasma to excite atoms and analyze multiple elements by light emission, while ICP-MS uses coupled plasma to ionize, separate and quantify ions.

Physical and Biological Parameters

Physical parameters like conductivity, pH, color and temperature can indicate the presence of organic and inorganic substances. Teams can evaluate these elements using field meters or laboratory instruments. Biological parameters, such as bacterial counts or biological oxygen demand (BOD), can indicate microbial activity.

2. Water-in-Oil Analysis

A water-in-oil analysis is beneficial for quality control. Refineries and many buyers require crude oil that meets specific content specifications. Excess water in oil reduces the oil’s value, and water in refined oil can cause engine problems in end products. Additionally, water in stored oil can settle and cause corrosion, causing problems for tanks, pipelines and other infrastructure.

Teams can test for excess water in oil by using several methods:

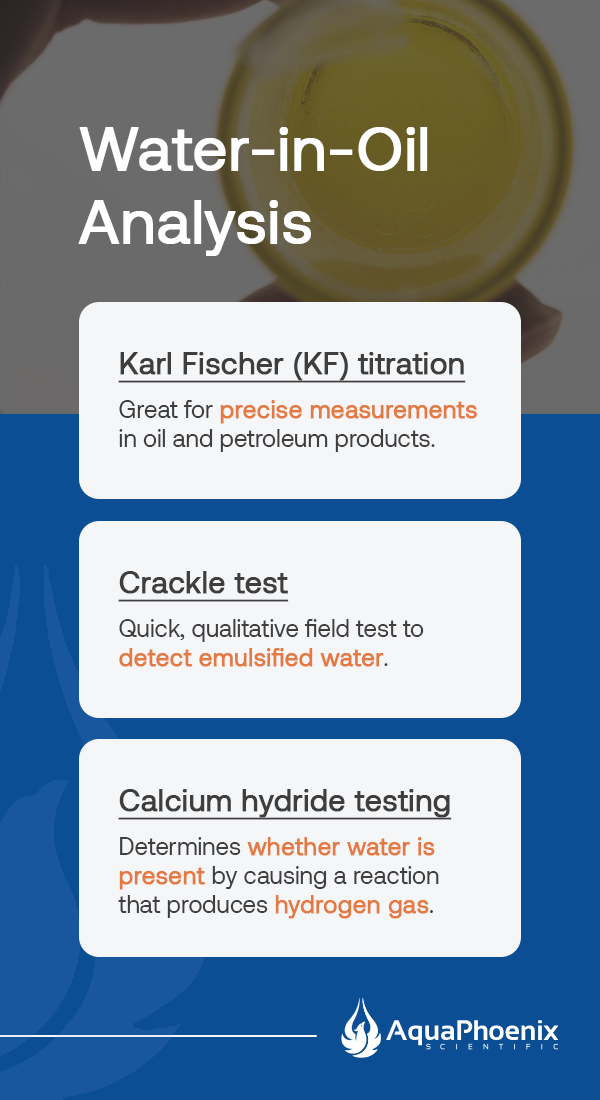

- Karl Fischer (KF) titration: This method is great for precise measurements in oil and petroleum products. KF titration is highly accurate, making it suitable for various water concentrations and oil types. It determines water quantity by using volumetric or coulometric titration. Volumetric titration involves dissolving samples in methanol and adding iodine to determine the endpoint. Coulometric titration detects the endpoint through electrochemical means.

- Crackle test: The crackle test is a quick, qualitative field test to detect emulsified water. This method requires minimal equipment but may not detect dissolved water. Testing the oil involves placing a sample on a hot plate with a temperature between the boiling point of oil and water. Sputtering, crackling or bubbling indicates the presence of water.

- Calcium hydride testing: Calcium hydride testing determines whether water is present by causing a reaction that produces hydrogen gas. Teams can use calcium hydride testing kits to complete an on-site analysis. Generally, these tests require adding oil to a container before sealing and shaking it. A manometer inside the container measures the pressure increase, which is directly proportional to the amount of water in the sample.

3. Well Testing

Well testing is the process of producing fluids temporarily from a well under controlled conditions. Teams can gather information to analyze the well’s performance, production potential and reservoir characteristics. This data is critical for improving reservoir management, optimizing production strategies and reducing risks in field development. There are several well testing techniques, including:

- Drawdown tests: A drawdown test or pressure transient test measures well performance. This process involves monitoring pressure changes as you produce a well at a constant rate. Generally, teams will shut down the well for a period before testing to allow the pressure to stabilize. After opening the well, teams can monitor the downhole pressure at a constant rate.

- Buildup tests: This test measures how reservoir pressure recovers after a well is shut following production. Buildup tests provide similar information to drawdown tests, but can be more reliable because the well is not flowing during measurement. During this test, teams monitor the pressure while the well is shut in.

- Injection tests: Injection tests use water, gas or another fluid injection to determine fracture pressure and evaluate EOR potential. These tests depict potential limitations, such as formation restrictions and wellbore damage. There are several types of injection tests, including tracer, step-rate and pressure buildup tests.

- Falloff tests: A falloff test is the counterpart to an injection test. This technique measures how pressure declines after stopping an injection. Teams analyze the pressure decline to determine parameters such as skin factor, permeability and reservoir boundaries.

- Interference tests: Interference tests evaluate the connectivity between wells by monitoring pressure changes in one well due to changes in another well. Typically, the process involves injecting fluid into one well and measuring the pressure response of the second. This test aids in determining well placement and the effectiveness of hydraulic fracturing.

Water Treatments for the Oil and Gas Industry

Various water treatments in the oil and gas industry remove contaminants and impurities from water sources and wastewater. The most common treatment methods are chemical treatments, filtration processes and separation techniques.

- Chemical treatments: Chemical treatments use scale inhibitors, corrosion inhibitors, biocides and other chemicals to remove water contaminants. This treatment type can effectively prevent corrosion, scale formation and bacterial growth.

- Filtration processes: This technique allows teams to physically remove solids and contaminants from water. Several types of filtration processes are available. Media filtration traps solids in gravel beds, sand or another medium. Cartridge or bag filters can remove fine particles, while other specialized media filters can remove oil and solids from produced water. Automatic self-cleaning filters can provide a continuous removal of solids in high-flow systems.

- Separation techniques: Separation techniques separate oil, solids and water based on physical property differences. Methods like centrifugation use centrifugal force to separate impurities, while electrocoagulation coagulates impurities with an electric current. Additional techniques can meet large-scale or specialized application needs.

Requirements and Compliance Needs

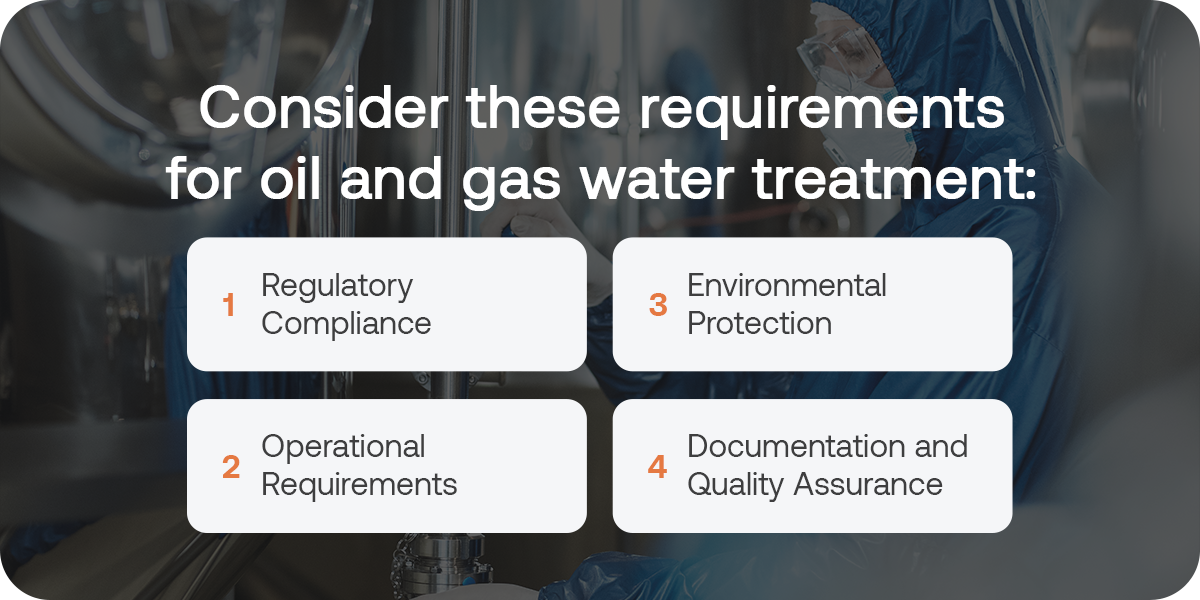

Operational needs, industry standards and protection initiatives shape the requirements for testing and water treatments in the oil and gas industry. Consider these requirements for oil and gas water treatment:

1. Regulatory Compliance

The oil and gas industry must adhere to federal and state regulations. Regulations from organizations like the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) aim to ensure safe and efficient operations. For example, OSHA outlines standards for hazardous and flammable materials. The EPA also requires teams to determine if wastewater is hazardous under the Resource Conservation and Recovery Act.

2. Operational Requirements

Operational requirements aim to protect equipment and promote process efficiency. Treating water prevents scaling, corrosion and fouling in processing equipment, wells and pipelines. Additionally, teams must meet water quality specifications for drilling, EOR, cooling systems and hydraulic fracturing. Operational requirements may vary by team and equipment needs. Generally, oil and gas teams can expect to complete operational monitoring and troubleshooting, product quality maintenance and equipment and infrastructure protection.

3. Environmental Protection

New regulations aim to remove or reduce chemicals, solids and hydrocarbons that can cause water or soil pollution due to oil and gas operations. Compliance requirements may include disposal or water reuse procedures. For example, the Clean Water Act outlines the responsibilities federal facilities have to prevent water pollution, meet water quality standards and develop risk management plans.

4. Documentation and Quality Assurance

The oil and gas industry is also subject to stringent documentation and quality assurance requirements. Regulatory bodies aim to ensure responsible water management and pollution prevention, and documentation supports team initiatives. Some documentation requirements could include chemical management programs, water quality monitoring data, permit applications, water management plans and risk assessments.

Common Challenges With Testing and Treatment

The complexity of oil and gas operations and regulatory and compliance needs present several challenges to testing processes. These challenges include:

- Complex water composition: Produced water can contain heavy metals, chemicals, microorganisms, solids and soils. With such a varied composition, teams may face challenges adopting robust testing protocols and treatment systems.

- High levels of contaminants: Water can also face high concentrations of contaminants like suspended solids, oil, grease and toxic substances. These high concentrations may demand multiple treatment stages or specialized equipment.

- Harsh operating environments: Oil and gas applications often occur in remote locations, under extreme temperatures, or in environments with high pressures. These harsh conditions can complicate testing and treatment operations, requiring laboratory access or increased equipment needs.

- Sampling issues: Inconsistent testing or sampling errors can lead to inaccurate test results. Without proper testing protocols and reliable testing equipment and techniques, teams may implement unnecessary treatments, wasting time and resources.

Request Oil and Gas Water Treatment Solutions

The oil and gas industry must comply with stringent requirements, meet buyer standards and complete safe operations to protect workers and the environment. Oil and gas teams looking to meet standards and improve operations can trust AquaPhoenix Scientific to deliver chemical processing and fracturing solutions.

AquaPhoenix Scientific offers testing products for hydraulic fracturing operations, downstream boiler monitoring, potable water testing, work-over applications, and boil and CO2 test products for EOR applications. We can also develop custom test kits to meet your unique needs. Contact our team to learn more about our testing solutions.